AGRO Multi boiler is intended for combustion of ecological fuel in form of pellet made of non-wood biomass. Raw materials for its production are e.g.: straw, Miscanthus, reed, kernels and seeds, olive residues and nut shells. Its optimized combustion process is ensured by innovative Multi PSQ burner [1]. Wide range or power allows limiting heat losses.

AGRO Multi is equipped with a new, multifunctional and simple controller ecoMAX 910 [2], which works with the outside sensor and room thermostat ecoSTER. The standard equipment of the controller includes 5 pumps: (central heating, domestic hot water, circulation pump, transfer pump and pump of the mixer) and two actuators of the mixing valves. Wide operation range of the controller allows setting various levels of the temperature in separate heating systems. For example: in floor heating and room heaters system. The ecoMAX 910 controller is equipped with a convenient graphical display and several options for additional equipment. Room controller ecoSTER TOUCH and the internet module ecoNET 300, giving an option of the remote preview, change of parameters and even technical support are the most important components.

Operational safety and protection of the device itself are ensured by a series of protections. Automatic fire suppression system, the so-called fire-fighter, is a basic equipment of the boiler. The sensors permanently control the temperature of water in the boiler, temperature of screw and fuel container. If the irregularities or damage of any of the sensors in the system is detected then the system gives an alarm signal and shuts down the feeder and fan. Jamming of the screw in the feeder results in mechanical rupture of split pin what protects the motoreducer against destruction. Another protection in AGRO Multi is a sensor protecting against retraction of glow to the feeder and flame suppression system when feeder pipe reaches a temperature of 90°C.

Non-wood pellet — granules produced from wastes from agricultural and forestry production. It is produced from grains, green stems, hay, energy crops and any other waste biomass, which can be combusted. This fuel is easy to transport and store, its price is considerably lower than price of wood pellet.

PEREKO boilers have high heating power with relatively small dimensions. It is also possible to install them in smaller boiler rooms.

Elongated flue gas circulation ensures higher efficiency of the equipment and lower fuel consumption.

Additional protection protecting against overheating and possible flashback to the charging hopper.

Steel burner Multi PSQ with a trough feeder has an innovative design allowing combusting pellet made of non-wood biomass.

An additional module allows controlling operation of the boiler via the internet.

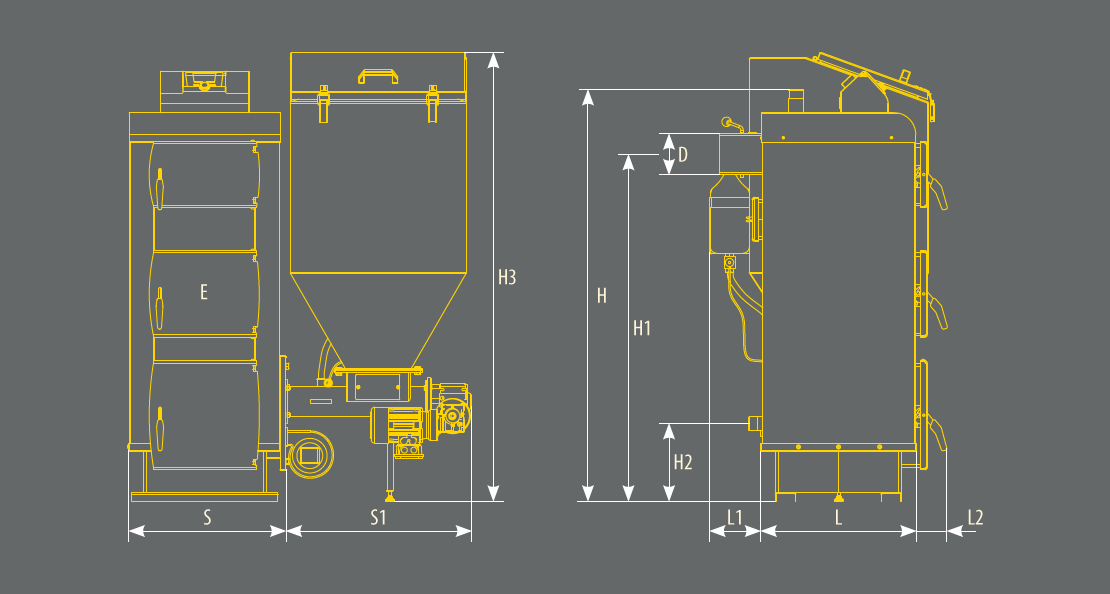

| Parameter | Unit | Model | |||

|---|---|---|---|---|---|

| 12 | 18 | 22 | |||

| Dimensions | D | [mm] | ∅ 159 | ∅ 178 | |

| E | [mm] | 248 × 173 | 268 × 198 | 348 × 248 | |

| L1 | [mm] | 220 | 180 | 140 | |

| L2 | [mm] | 180 | 140 | ||

| L | [mm] | 420 | 525 | 595 | |

| H | [mm] | 1260 | 1385 | 1410 | |

| H1 | [mm] | 1060 | 1155 | 1180 | |

| H2 | [mm] | 305 | 310 | ||

| H3 | [mm] | 1215 | 1560 | ||

| S | [mm] | 460 | 510 | 600 | |

| S1 | [mm] | 550 | 650 | ||

| Primary fuel | — | non-wood pellet | |||

| Range of thermal power* | [kW] | 3 – 12 | 5 – 18 | 8 – 22 | |

| Area of heated rooms** | [m²] | do 218 | do 327 | do 400 | |

| Heated rooms volume | [m³] | do 545 | do 818 | do 1000 | |

| Charging capacity of container | [dm³] | 150 | 300 | ||

| Boiler water tank capacity | [dm³] | 38 | 50 | 65 | |

| Heat exchanger material | — | Steel P265GH [PN-EN 10028]; thickness 5 and 6 mm | |||

| Maximum working pressure | [bar] | 1,5 | |||

| Required min. chimney draught*** | [Pa] | 20 | 25 | ||

| Power supply / Power | [V/W] | 230 / 175 | |||

| Weight of boiler without water | [kg] | 278 | 370 | 436 | |

| Energy-efficiency rating | — | A+ | |||

| 5th class acc. to the PN EN 303-5:2012 | — | no | |||

| The boiler meets the ECODESIGN requirements | — | no | |||

| The boiler meets the requirements of the REGULATION OF THE MINISTER OF DEVELOPMENT AND FINANCE of 1 August 2017 on the requirements for solid fuel fired boilers |

— | yes | |||

| Control | — | controller ecoMAX 910 | |||

| Additionally as a standard | — | “FIRE-FIGHTER” kit | |||

| Burner | — | Multi PSQ | |||

| Additional equipment |

|

||||

| Warranty | — | 10-year warranty for tightness of welds 5-year warranty for tightness of heat exchanger 2-year warranty for components |

|||