KSM series

Primary fuel: eco-pea coal

5th class of emission, modern design

and high efficiency of the device

– reaching 91%.

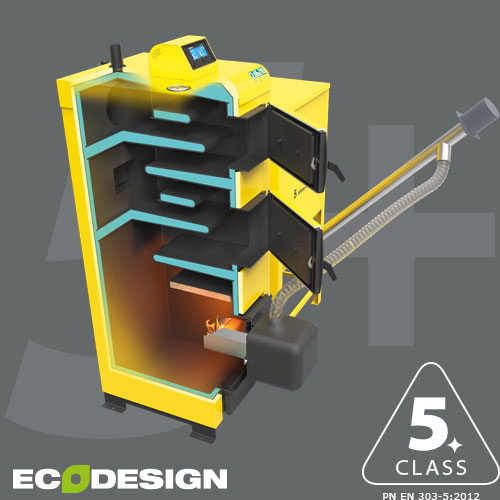

KSP Pelet series

Primary fuel: wood pellet

Boiler fired with pellet with 5th class of emission, smooth adjustment of power and automatic igniter.

KSP Spark series

Primary fuel: wood pellet

Innovative pellet combustion system.

One of the most economical device available on the market – efficiency ~ 93%.

KSR Beta Pelet series

Primary fuel: wood pellet

The classic body of the KSR series, adapted for combustion of pellet, automatic igniter and a wide range of power.

NEWS