KSP Pelet boiler has been designed with a view to heating, which is environmentally friendly. It has the highest 5th class of emission (applies to model 20 kW) acc. to the PN EN 303-5:2012 standard and the ECODESIGN certificate. Various types of pellets (made of wood, straw, shells, seeds of e.g. sunflower) are dedicated fuel to the KSP Pelet. Granules of the wood pellet are almost completely burnt, leaving small amounts of ash, which can be used as a good-quality fertiliser. High heating value of the pellet together with an automatic ignition function, smooth adjustment of power and low energy consumption additionally influences the economical operation of the boiler.

KSP Pelet is an innovative achievement in the range of solid fuel fired boilers with respect to the efficiency, automation of servicing and care for the natural environment. The ergonomic design of the equipment allows flexible adaptation of power to the size of the heated area and therefore it eliminates a common problem of overdimensioning leading to power losses. The high efficiency of the device (94%) and minimized necessity of cleaning was achieved due to a new design of the heat exchanger. The boiler is extremely functional due to its small sizes, option to set charging hopper [1] in any place in the boiler room and installation of doors [2] on the right or left side.

Operation of the device is controlled by a modern control system PELLAS [3] with smooth control FUZZY LOGIC, which services three pumps (central heating, domestic hot water and floor), drive of the mixing valve and temperature limited (STB). Furthermore, it is responsible for the start-up of the boiler, control of power level and cleaning. Automatic igniter allows automatic firing up at any time indicated by the user. In case of power shortage the boiler is able to continue operation after its recovery because all settings are saved in the system memory. An extended time of service-free operation of the boiler is reached due to use of special fuel mixing process in the furnace chamber. Innovative overpressure combustion method protecting against flashback and continuous monitoring of temperature ensures improved operational safety.

Wood pellet is a compressed biomass formed from the wood waste. It is produced in form of granules having the length of several centimetres. It has high calorific value and low moisture content. It does not leave dirt, has a pleasant smell, is easy to transport and store.

PEREKO boilers have high heating power with relatively small dimensions. It is also possible to install them in smaller boiler rooms.

Certificate from accredited laboratory confirming meeting the requirements of the 5th emission class allows obtaining co-financing for the purchase of the equipment.

The most effective use of the fuel from all equipment of its class that are available on the market.

The most technologically advanced solution used in the solid fuel fired boilers. It is intended for combustion of biomass such as pellet, oats and kernels.

An additional module allows controlling operation of the boiler via the internet.

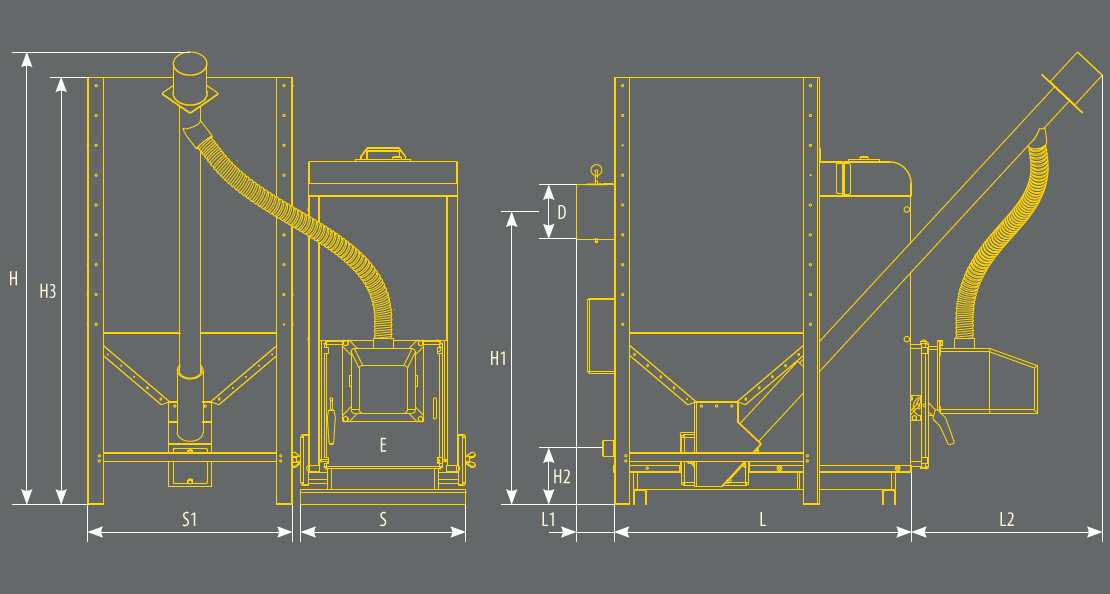

| Parameter | Unit | Model | |

|---|---|---|---|

| 20 | |||

| Dimensions | D | [mm] | ∅ 159 |

| E | [mm] | 344 × 268 | |

| L1 | [mm] | 110 | |

| L2 | [mm] | 530 | |

| L | [mm] | 880 | |

| H | [mm] | 1300 | |

| H1 | [mm] | 845 | |

| H2 | [mm] | 150 | |

| H3 | [mm] | 1250 | |

| S | [mm] | 490 | |

| S1 | [mm] | 610 | |

| Primary fuel | — | pelet | |

| Range of thermal power* | [kW] | 0 – 20 | |

| Area of heated rooms** | [m²] | do 364 | |

| Heated rooms volume | [m³] | do 909 | |

| Charging capacity of container | [dm³] | 300 | |

| Boiler water tank capacity | [dm³] | 95 | |

| Maximum working pressure | [bar] | 1,5 | |

| Required min. chimney draught*** | [Pa] | 20 | |

| Power supply / Power | [V/W] | 230 / 1200 | |

| Weight of boiler without water | [kg] | 375 | |

| Energy-efficiency rating | — | A+ | |

| 5th class acc. to the PN EN 303-5:2012 | — | yes | |

| It meets the ECODESIGN requirements | — | yes | |

| The boiler meets the requirements of the REGULATION OF THE MINISTER OF DEVELOPMENT AND FINANCE of 1 August 2017 on the requirements for solid fuel fired boilers |

— | yes | |

| Heat exchanger material | — | Steel P265GH [PN-EN 10028]; thickness 5 and 6 mm | |

| Control | — | controller R.Control | |

| Burner | — | Burner fired with pellet X + galvanized feeder, 2-metres long | |

| Additional equipment | — |

|

|

| Warranty | — | 10-year warranty for tightness of welds 5-year warranty for tightness of heat exchanger 2-year warranty for components |

|