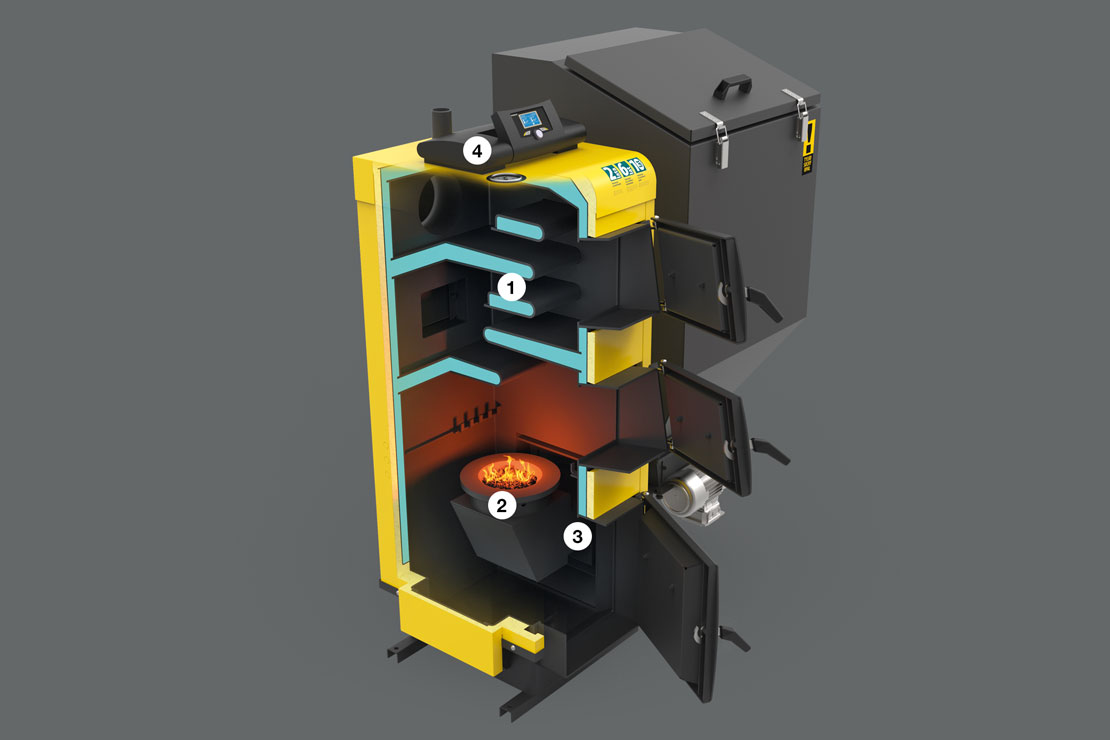

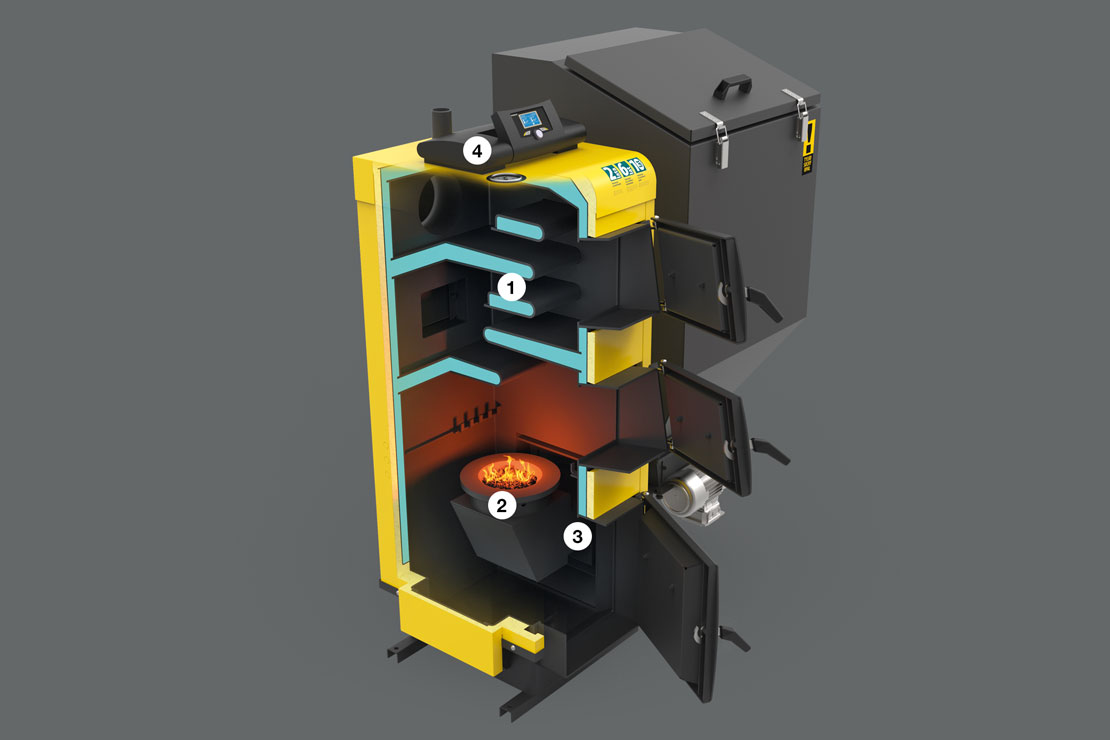

KSR Beta boilers can be reliably used in everyday operation. Design of body and heat exchanger [1] ensures the most effective transfer of heat, tightness for many years of operation and high reliability. It results from use of the high-quality materials and components already proven in operation. Eco-pea coal is a primary fuel for the KSR Beta series equipped with a retort burner PSR [2].

These boilers are convenient and convenient in operation. Using the retort burner [3], binary controller and fan, improves the efficiency, lowers failure frequency and significantly shortens the time necessary for servicing of the equipment. ecoMAX 910 [4] controller continuously takes care of the combustion process ensuring optimum dosing of fuel and inflow of air. It controls also the operation of four pumps: central heating, domestic hot water, circulation pump and pump of the mixer. Precise control ensures obtaining the set temperature using the lowest portions of the fuel, what causes that the equipment is one of the cheapest in operation. The KSR Beta boilers can be additionally equipped with the Internet modules responsible for remote control. While installation of the additional automatic suppression system (so-called “fire-fighter”) allows combustion of the pellet.

Several temperature sensors ensure maximally safe operation of the boiler. If the too high level of heat (85-90°C) is recorded then they initiate alarm signal and shutdown of the feeder and fan. Pumps are activated in case of a sudden increase in temperature and they distribute hot water through the system. The equipment reacts also to overheating of the screw in the feeder, lack of fuel and a problem with reaching the set temperature. A split pin located in the feeder protects the motoreducer and it will be ruptured when the screw is locked protecting the boiler against destruction.

Eco-pea coal is a coal with a grain size 5-25 mm intended for modern boilers with a retort feeder. It characterizes with high calorific value and low content of sulphur and ash. This product is produced from selected coals with the best available parameters.

PEREKO boilers have high heating power with relatively small dimensions. It is also possible to install them in smaller boiler rooms.

Vertical shelves in the heat exchanger allow easy cleaning of boiler interior.

Professional controller individually adapted for each boiler. Its operation does not require professional knowledge from the user.

It ensures clean combustion and non-disturbed operation. PSR feeder is intended for use of eco-pea coals and pellets with granulation not greater than 31.5 mm.

An additional module allows controlling operation of the boiler via the internet.

| Parameter | Unit | Model | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 15 | 20 | 25 | 28 | 35 | 50 | 70 | |||

| Dimensions | D | [mm] | ∅ 159 | ∅ 178 | ∅ 219 | ||||

| E | [mm] | 248 × 173 | 298 × 198 | 348 × 248 | |||||

| L1 | [mm] | 110 | 150 | ||||||

| L2 | [mm] | 220 | |||||||

| L | [mm] | 495 | 525 | 595 | 675 | 870 | |||

| H | [mm] | 1275 | 1385 | 1410 | 1565 | 1770 | |||

| H1 | [mm] | 1065 | 1155 | 1180 | 1335 | 1530 | 1520 | ||

| H2 | [mm] | 310 | 320 | ||||||

| H3 | [mm] | 1140 | 1560 | 1600 | |||||

| S | [mm] | 460 | 510 | 590 | 700 | 720 | |||

| S1 | [mm] | 600 | 650 | 900 | |||||

| Primary fuel | — | eco-pea coal | |||||||

| Range of thermal power* | [kW] | 4 – 15 | 5 – 20 | 6 – 25 | 8 – 28 | 10 – 35 | 15 – 50 | 21 – 70 | |

| Area of heated rooms** | [m²] | do 273 |

do 364 |

do 455 |

do 509 |

do 636 |

do 909 |

do 1273 |

|

| Heated rooms volume | [m³] | do 682 |

do 909 |

do 1136 |

do 1273 |

do 1591 |

do 2273 |

do 3182 |

|

| Charging capacity of container | [dm³] | 150 | 300 | 900 | |||||

| Boiler water tank capacity | [dm³] | 52 | 70 | 75 | 96 | 102 | 130 | 152 | |

| Heat exchanger material | — | Steel P265GH [PN-EN 10028]; thickness 5 and 6 mm | |||||||

| Maximum working pressure | [bar] | 1,5 | |||||||

| Required min. chimney draught*** | [Pa] | 20 | 25 | 30 | |||||

| Power supply / Power | [V/W] | 230 / 175 | |||||||

| Weight of boiler without water | [kg] | 264 | 348 | 377 | 419 | 456 | 623 | 763 | |

| Energy-efficiency rating | — | D | |||||||

| Control | — | controller ecoMAX 910 | |||||||

| Additionally as a standard | — | emergency cast-iron grate | |||||||

| Burner | — | PSR | |||||||

| Additional equipment | — |

|

|||||||

| Warranty | — |

|

|||||||