KSW Alfa is based on a design already proven in operation for many years. The current version was upgraded. The simplest, but very effective boiler, is the best choice for heating of small and medium buildings. It is intended mainly for combustion of coal but it can be also used for combustion of the other type of fuel.

For the production of boilers we use good quality of steel. Together with double welds it ensures long-term integrity and improved resistance to corrosion. Warranty periods for this model: 2 years of warranty for components, 6 years warranty for tightness of heat exchanger and 10 years for tightness of welds.

The simple design means also a simple operation. This boiler can beeasily operated by every user using his past experience. We have widened the doors {1} and placed it a slight angle to increase the convenience of fuel charging. A handy lever [3] was installed on the side of the boiler to clean the grate [2] from formed ash. Just pull it and whole ash will fall down to the ash-pan [4].

The classic design was improved by development by longer flue gas circulation [5]. In this way we prolonged operation time on one charge. As a result you will use less fuel during combustion in this boiler.

Design allows development in the future - connection of controller and fan. Additional components increase urn time and facilitate firing up of the boiler by improving chimney draught. When the user wants to stay with a traditional service we suggest installation of draught regulator. It maintains set temperature of heating water by mechanical control of air inflow to the combustion chamber.

Hard coal is the most often used type of fuel for heating the house.

High calorific value and relatively low price are the main factors decisive on its popularity.

PEREKO boilers have high heating power with relatively small dimensions. It is also possible to install them in smaller boiler rooms.

Vertical shelves in the heat exchanger allow easy cleaning of boiler interior.

The connection of boiler to the chimney is no longer a problem due to universal connection ensuring high accessibility.

A lever located on the side of the boiler services mobile grate set at a slight angle in vertical motion what facilitates removal of ash.

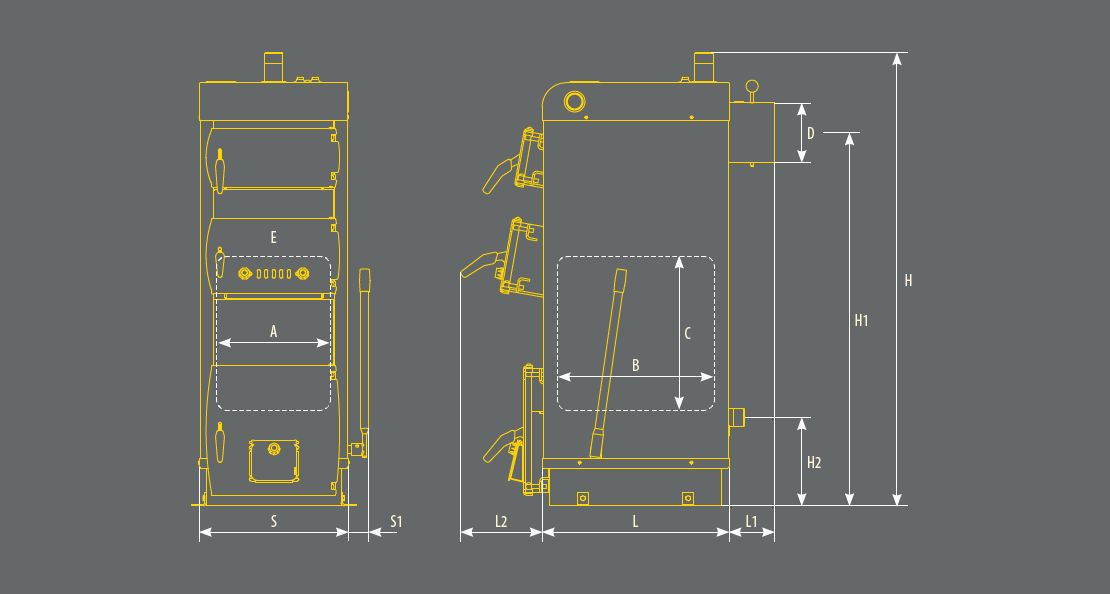

| Parametr | Unit | Model | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 5 | 9 | 12 | 16 | 18 | 20 | 24 | |||

| Dimensions | A | [mm] | 250 | 290 | 340 | ||||

| B | [mm] | 290 | 320 | 390 | 420 | ||||

| C | [mm] | 340 | 325 | 390 | 380 | 340 | 365 | ||

| D | [mm] | ∅ 127 | ∅ 159 | ||||||

| E | [mm] | 248 × 173 | 298 × 198 | ||||||

| L | [mm] | 400 | 425 | 495 | 525 | ||||

| L1 | [mm] | 110 | |||||||

| L2 | [mm] | 200 | 220 | ||||||

| H | [mm] | 860 | 1080 | 1115 | 1200 | 1205 | 1265 | ||

| H1 | [mm] | 695 | 915 | 910 | 990 | 975 | 1035 | ||

| H2 | [mm] | 210 | 235 | ||||||

| S | [mm] | 370 | 390 | 440 | |||||

| S1 | [mm] | 65 | |||||||

| Primary fuel | — | hard coal | |||||||

| Thermal power* | [kW] | 5 | 9 | 12 | 16 | 18 | 20 | 24 | |

| Area of heated rooms** | [m²] | ≤ 91 |

≤ 164 |

≤ 218 |

≤ 291 |

≤ 327 |

≤ 364 |

≤ 436 |

|

| Heated rooms volume | [m³] | ≤ 227 |

≤ 409 |

≤ 545 |

≤ 727 |

≤ 818 |

≤ 909 |

≤ 1091 |

|

| Efficiency | [%] | ~80 | |||||||

| Power control range | [%] | ±2 | |||||||

| Capacity of combustion chamber | [dm³] | 20 | 27 | 33 | 35,5 | 45 | 53 | ||

| Boiler water tank capacity | [dm³] | 20 | 28 | 38 | 52 | 55 | 70 | 75 | |

| Heat exchanger material | — | Steel P265GH [PN-EN 10028]; thickness 6 mm | |||||||

| Maximum working pressure | [bar] | 1,5 | |||||||

| Required min. chimney draught*** | [Pa] | 20 | 23 | 25 | |||||

| Min./max. water temperature | [°C] | 57/95 | |||||||

| Power supply / Power | [V/W] | 230/85 | |||||||

| Weight of boiler without water | [kg] | 129 | 148 | 181 | 202 | 214 | 248 | 253 | |

| Diameter of water connection | [cal] | G 1 1/2 | |||||||

| Energy-efficiency rating | — | E | D | ||||||

| Control | — | none | |||||||

| Additionally as a standard | — | set of cleaning tools | |||||||

| Additional equipment | — |

|

|||||||

| Warranty | — |

|

|||||||